The expert consultant team of LeanFour Technologies is composed of senior in-plant material management and IT experts from Germany and China, with an average of more than 15 years of experience in the industry. Our team has rich experience and technical expertise in the field of in-plant material management and information technology, and has long-term practical experience in successfully providing in-plant logistics planning for domestic and foreign first-line brand companies.

Usually, we will start planning services for customers according to the following content and steps:

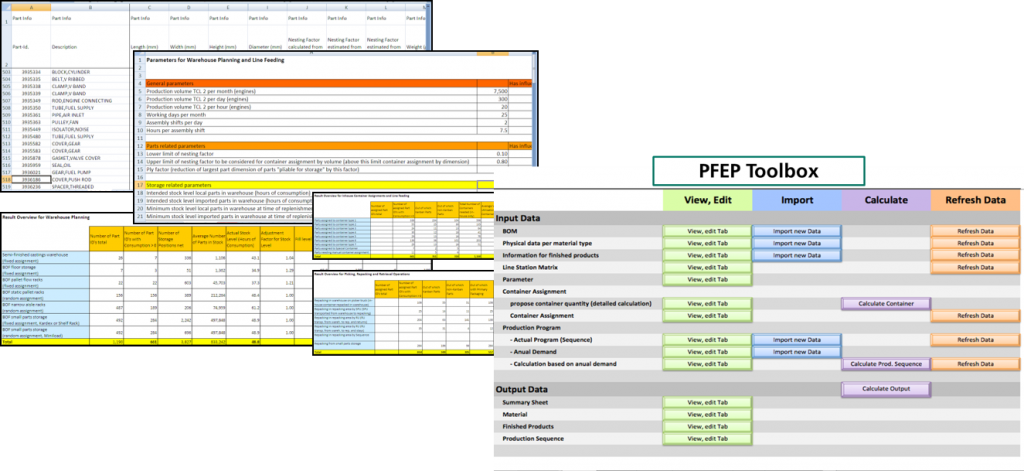

Planning Work Package 1(WP1):Set up PFEP Data Book

PFEP (Plan For Every Part) through a quantitative model, helps customers to plan each material from supply sourcing , delivery mode, unit-load type, stock level, to line feeding (or production pull) mode, as well as line side buffer level and presentation, so as to establish a data basis for subsequent in-plant logistics planning.

A comprehensive PFEP Data Book can not only be used for in-plant logistics planning and design under current business scenarios, but also can help customers use it for future scenario design on the premise of helping customers master the use of PFEP Data Book.

Our PFEP Tool Kits are derived from long-term practical experience in planning for industry-leading companies, which can help customers quickly identify the planning parameters that need to be captured, and verify the input data, to quickly establish the PFEP Data Book.

Planning Work Package 2(WP2):In-house Material Flow Map set up

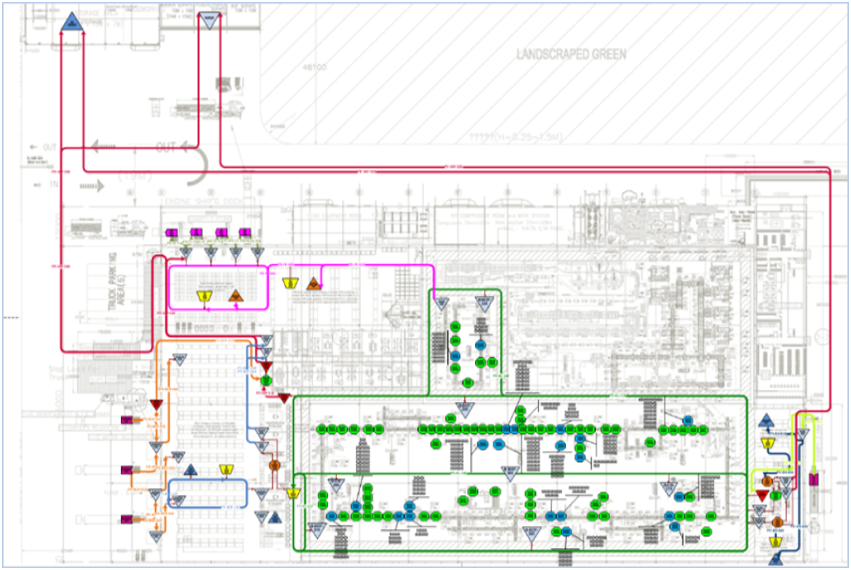

The Material Flow Map is a (static) graphical model of the logistics operations, which compiles all intra-logistics functions to be considered during planning within the scope of the project, in particular receiving, warehousing, buffering, picking, repacking, operations (non-logistics function, such as manufacturing, assembly etc.), shipping and internal transport. The model uses a set of graphical building blocks, which are set against the background of the plant layout for clarity.

In the detailed planning phase, the key logistics elements in the material flow map will be defined in detail, and the material flow logic between the logistics nodes will be planned and designed.

Example:

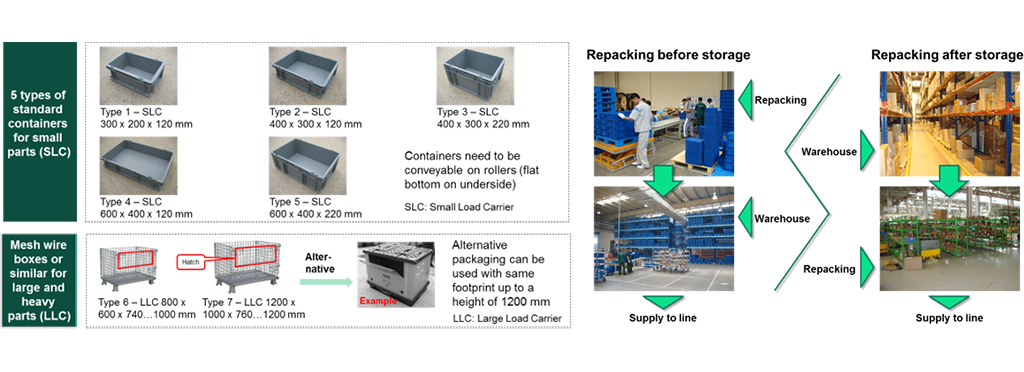

Planning Work Package 3(WP3):Parts Unit Load Planning

In this step a set of standard containers for in-house use, in particular for line feeding (and potentially for use as returnable containers to/from suppliers) is defined, and parts are assigned to these standard container types (unless parts require special containers) according to a set of rules making use of physical parts data, consumption data and ergonomic requirements.

Example:

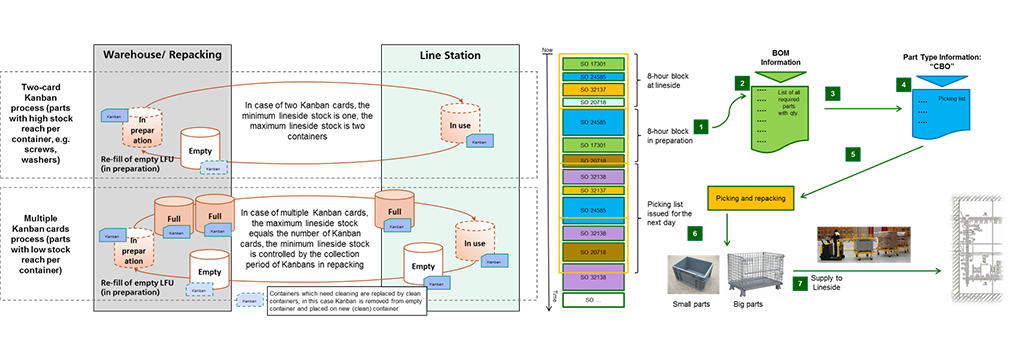

Planning Work Package 4(WP4): Planning of Line Feeding Mode, Line Side Presentation

In this planning step, the line feeding mode of each material will be planned, as well as determining the stock level in line side, line feeding cycle time, line side presentation layout and storage type and so on. The planning will comprehensively consider factors such as order characteristics, material frequency of use, assembly characteristics, line side layout, process requirements and other factors.

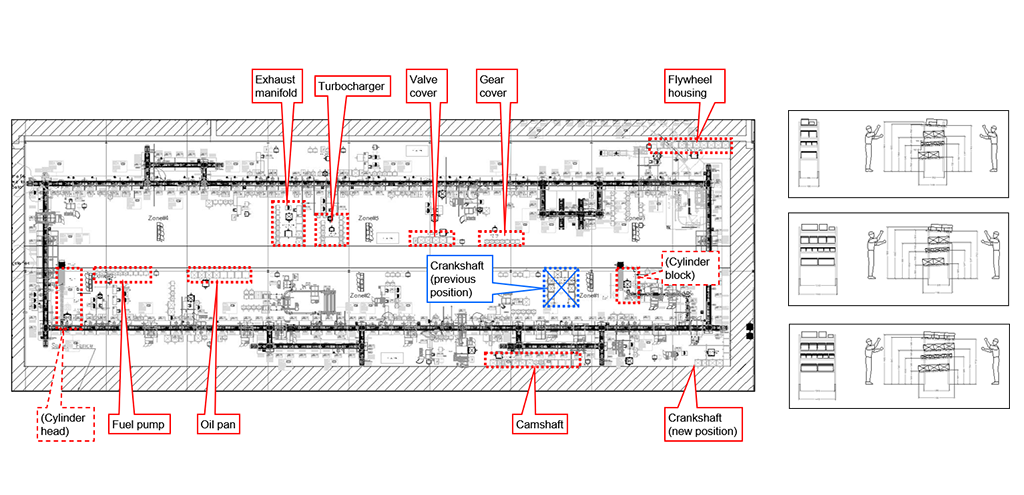

Example:

Line feeding mode:

Line side presentation:

Planning Work Package 5(WP5): Planning of Warehouses, Buffer, Picking, Kitting, Sequencing and Repacking Areas

In this step the detailed planning of all warehouses, material buffers, re-packing, picking, kitting and sequencing areas for line supply is carried out by implementation phase, in particular:

- Review and optimization of whole logistics areas

- Warehouse spaces and other functional areas

- Arrangement of functional areas to allow for an efficient material flow

- Planning the warehouses and buffer areas for

- Receiving and income inspection

- BOF warehouse

- Repacking, picking and kitting areas

- Spare parts storage/package/shipping

- Indirect material storage, other supporting area, etc.

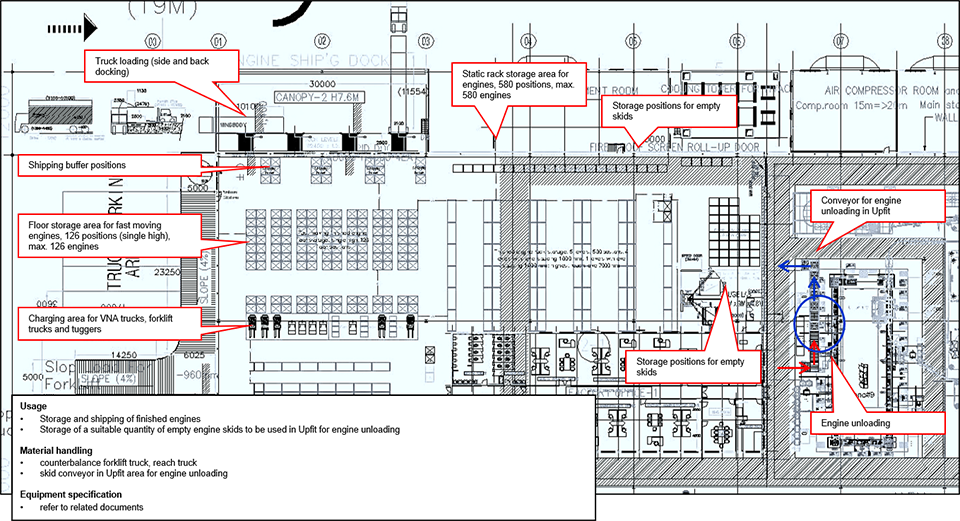

Example:

Planning Work Package 6(WP6): Planning of Transport Routes and Transport Equipment

In this step the in-house transport routes and the equipment used for transport are planned by implementation phase.

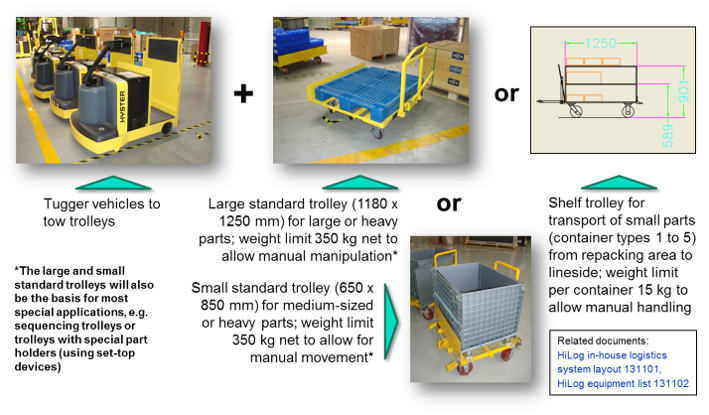

Example:

Planning Work Package 7(WP7): Intra- Logistics Process Planning

In the former planning steps the physical intra-logistics operations have been planned and described. In this step the corresponding organizational processes are worked out, for example,

- Warehousing processes

- Supply to picking/kitting/sequencing areas from BOF warehouse/repacking area

- Call from main assembly line/sub-assemblies/engine upfit to picking/kitting/sequencing areas

- Indirect material management process

- Container disposal and recycling process

- NCM (Non Conformance Material) / Out of Process material handling process, etc.

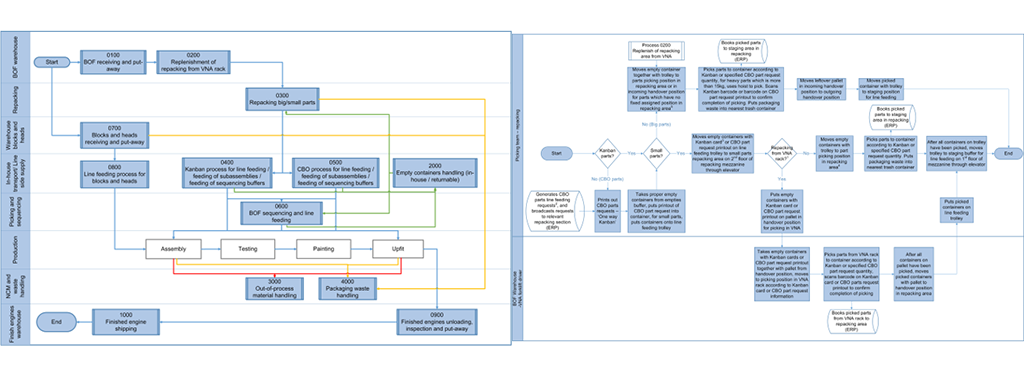

Example:

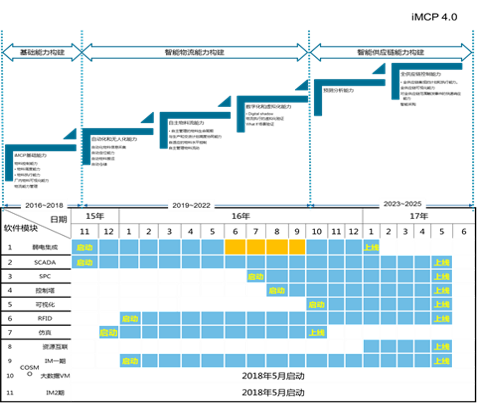

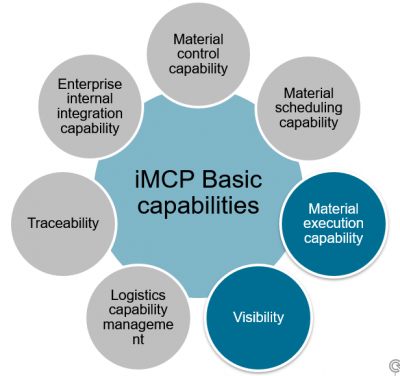

Planning Work Package 8(WP8): Intra- Logistics IT Planning

In this step, the corresponding in-house material control system IT will be planned to ensure that the objectives of the previous planning are effectively supported and successfully implemented. The planning scope includes,

- Develop of capacity model of (Smart ) In-house material control system,

- IT road map for implementation

- In-house material control system process and functional planning

- In-enterprise material control system integration planning (with ERP/MES/APS)

- (Optional) BA, system requirements specification development, implementation support

Example:

Optional Work Contents

- Wastes and empty container handling

- Planning of manpower required to run the intra-Logistics Functions

- Key Inhouse material flow simulation

- Training of customer staff regarding the planning results and the usage of the planning Data Book

- Support of the customer team during the implementation phase

Please contact LeanFour for the latest information about Intra-logistics planning!